Circular Manufacturing

Using waste as fuel. Sealing the deal on our patented circular manufacturing process.

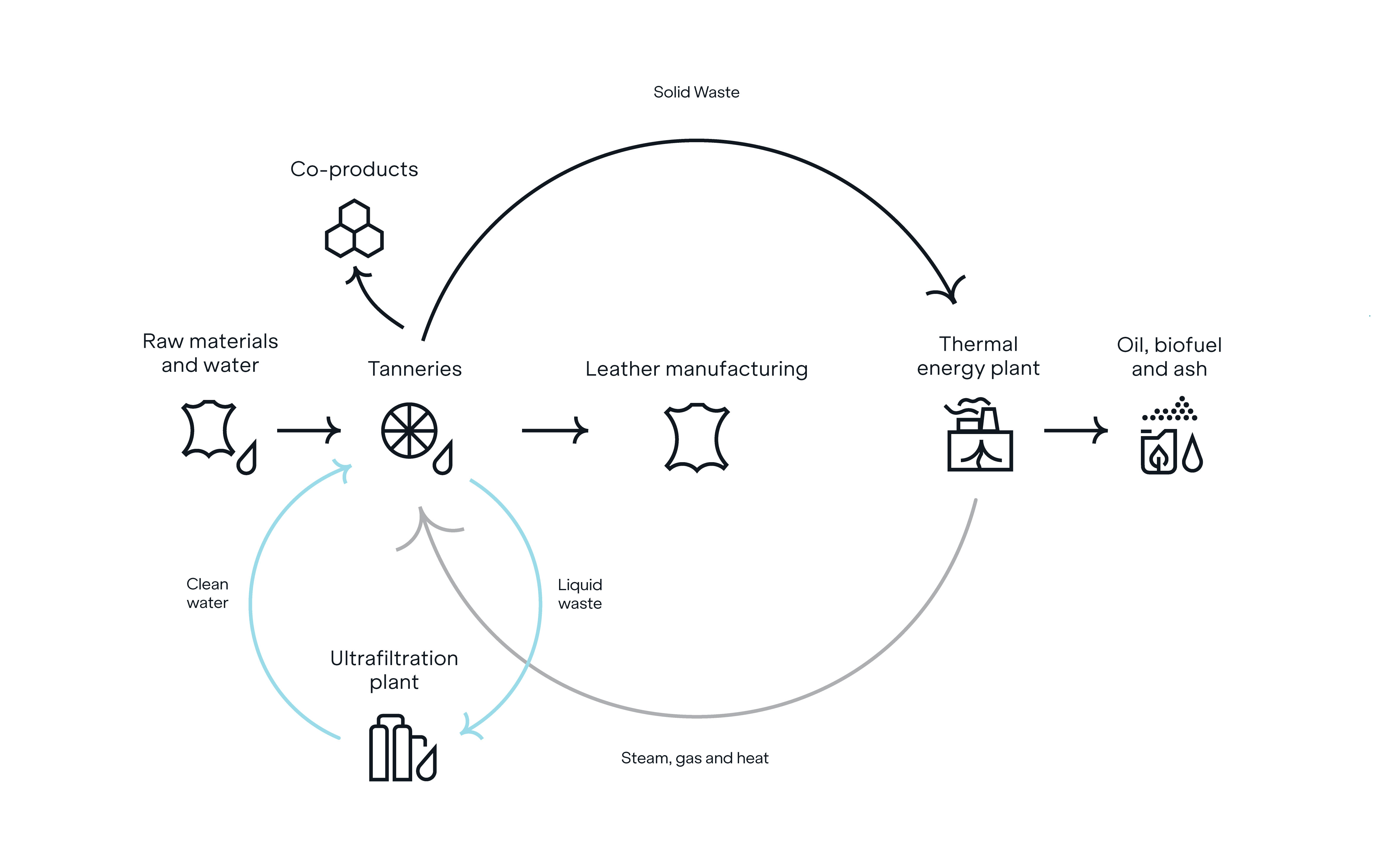

Not only do we convert solid waste to steam, we have an innovative take-back scheme that converts end-of-life leather into fuel for our thermal energy plant. Old leather contributes to the manufacture of new - a circular manufacturing process.

We are proud to be a Circular Glasgow ambassador, putting Scotland at the forefront of the circular economy.

When it comes to the tanning process, this is where our circular manufacturing comes into its own.

We generate co-products which are sold on to be re-used as raw materials in a wide range of other industries, including the food and biofuel sectors.

In developing our own renewable-driven, self-heating system, up to 94% of our waste per week is now recycled or recovered. This reduction in landfill is a major landmark in our journey to zero waste (Scopes 1 & 2) by 2025.

Our circular manufacturing process.

Our commitments and progress.

2025

We are committed to reducing our direct (scope 1 and scope 2) impact to Net Zero as reported under SECR, which has already reduced by 90% from baseline towards our 2025 target.

2028

5% of our suppliers by emissions covering purchased goods and services will have science-based targets.

2030

To continue active annual sourcing of 100% renewable electricity.

2034

To reduce absolute Scope 1, 2 and 3 GHG emissions 67.2% from a FY2018 base year.

To reduce Scope 3 FLAG GHG emissions by 48.5% from a FY2018 base year (including FLAG emissions and removals).

ESG Report.

Our annual Environmental, Social and Governance (ESG) Report summarises our activities, commitments and innovation agenda. All supporting and driving us towards a more sustainable future.